what are the three basic areas of a machine that require safeguarding

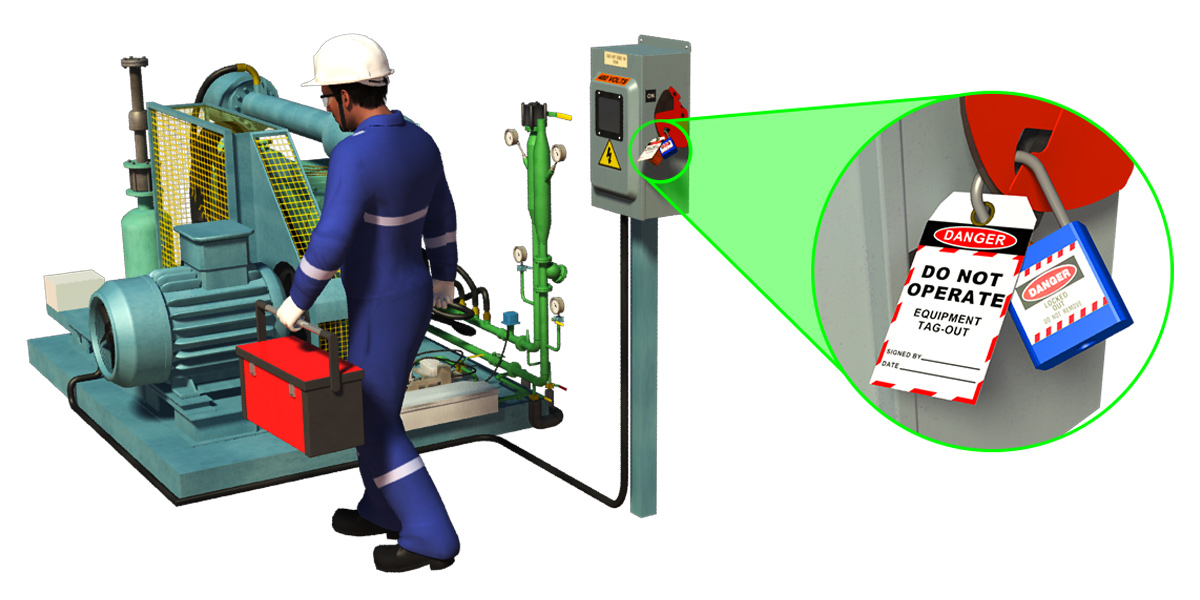

Safeguarding There are many ways to safeguard machines. All components of the mechanical system which transmit energy to the part of the machine performing the work.

Machine Guards Eliminate Hazards For Employees Article The United States Army

Despite all machines having the same basic components.

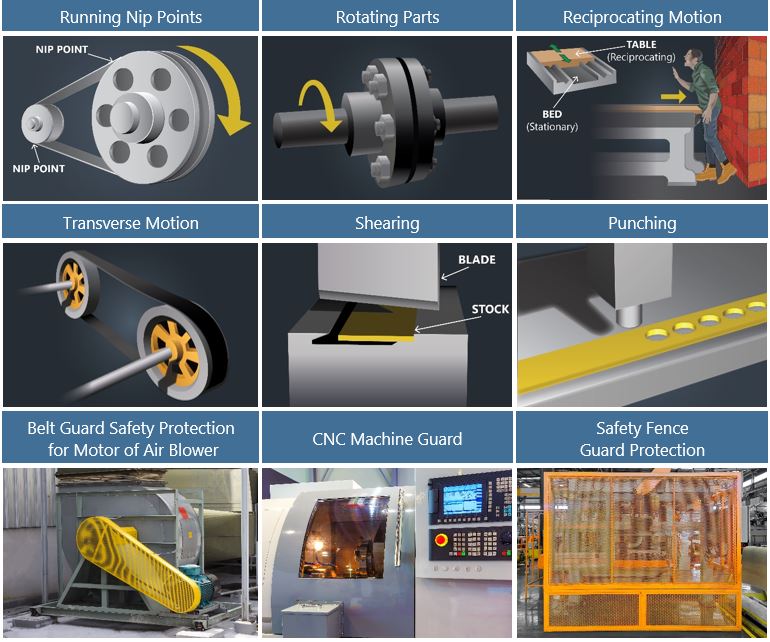

. The point of operation the power transmission device and the operating controls. The safeguard must prevent hands arms or any other part of a workers body from contacting. Point-of-operation safeguarding is usually designed with two primary objectives.

The point of operation. Determine the appropriate safeguarding method. That point where work is performed on the material such as cutting shaping boring or forming of.

Three basic area require machine safeguarding. What are the three basic areas of a machine that require safeguarding. What are the three basic areas of a machine that require safeguarding.

All components of the mechanical system which transmit energy to the part of. Prevent hazardous machine motion during human. Point of Operation Power Transmission Apparatus Other Moving Parts Question 2.

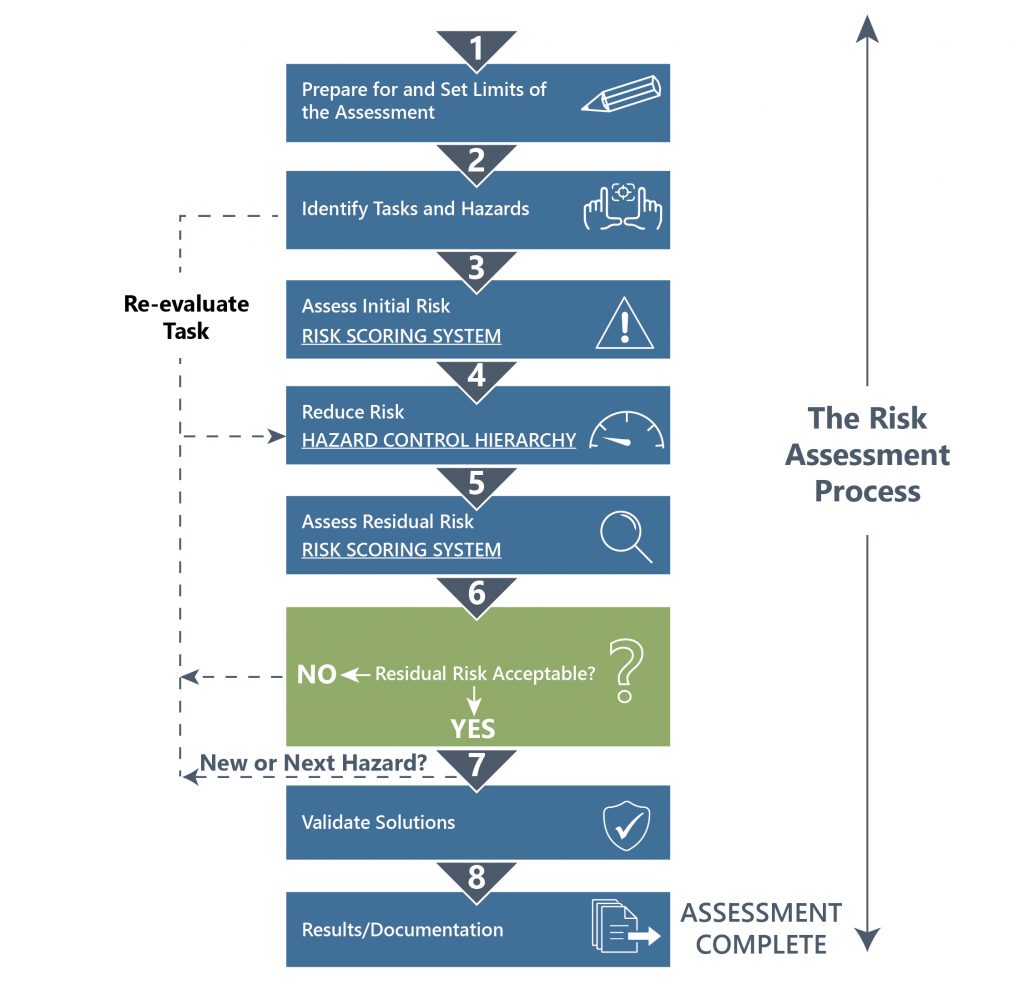

The purpose of machine guarding is to protect the machine operator and other employees in the work area from hazards created during the machines normal operation. Dangerous moving parts that need safeguarding are located in the three basic areas described below. What are the three basic areas of a machine that require safeguarding.

The type of operation and material the size or shape of stock. The point of operation. The point of operation the power.

All machines consist of three fundamental areas. Friday May 6 2022. The point of operation is the point where.

That point where work is performed on the material such as cutting shaping boring or forming of. Dangerous moving parts in three basic areas require safeguarding. What is the criteria for a guard having to be used on a machine select the best option.

Machine safeguards must meet these minimum general requirements. Requirements for Safeguards Machine safeguards must meet these minimum general. Machine Guarding eTool All machines consist of three fundamental areas.

Prevent human access during hazardous machine motion. Dangerous moving parts in three basic areas require safeguarding. Guards shall be affixed to the machine where possible and secured elsewhere if for any reason attachment to the machine is not possible to prevent access to the hazard from all accessible.

Six Types Of Machine Safeguard Devices

Six Types Of Machine Safeguard Devices

Chapter 1 Basics Of Machine Safeguarding

The Guarded Truth Answers To Machine Guarding Compliance Faqs Ensafe

The Guarded Truth Answers To Machine Guarding Compliance Faqs Ensafe

Top 10 Golden Safety Rules For Machine Guarding Ask Ehs Blog

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Skills Children Need To Thrive Technology Skills Critical Thinking List Of Skills

Concepts Techniques Of Machine Safeguarding Chapter 2

Six Types Of Machine Safeguard Devices

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Machine Guarding For Workplace Safety Safesite

Comments

Post a Comment